Design Feature #50

B.Y.O.R. —— Building Your Own Roaster

Handyman Roasters

Text: TL ling

Translated by: Venus Purnama

Image: Handyman Roasters, PMQ

There’s no denying that in Hong Kong, some are crazy for the stock market, some are fond of roasting coffee beans. For the one who is crazy for coffee, they would rather go for a roaster. And it’s not news at all. Naam Yu, product designer, has built the roaster all by himself. He used a hammer and plenty of stainless steel plates to carry on his D.I.Y., despite all the trial and error along the way.

“I have been working on the roaster for the past three years. Hitting the wall from time to time, I would feel frustrated. Then I sat back and asked myself, whether the journey should end or not.” He would stop for a while when feeling down. “It was like having a relationship, getting through all the roughs and toughs. I couldn’t help but get back to work when I saw the roasting machine was full of dust.”

Roasting up a Design Storm in a Claypot

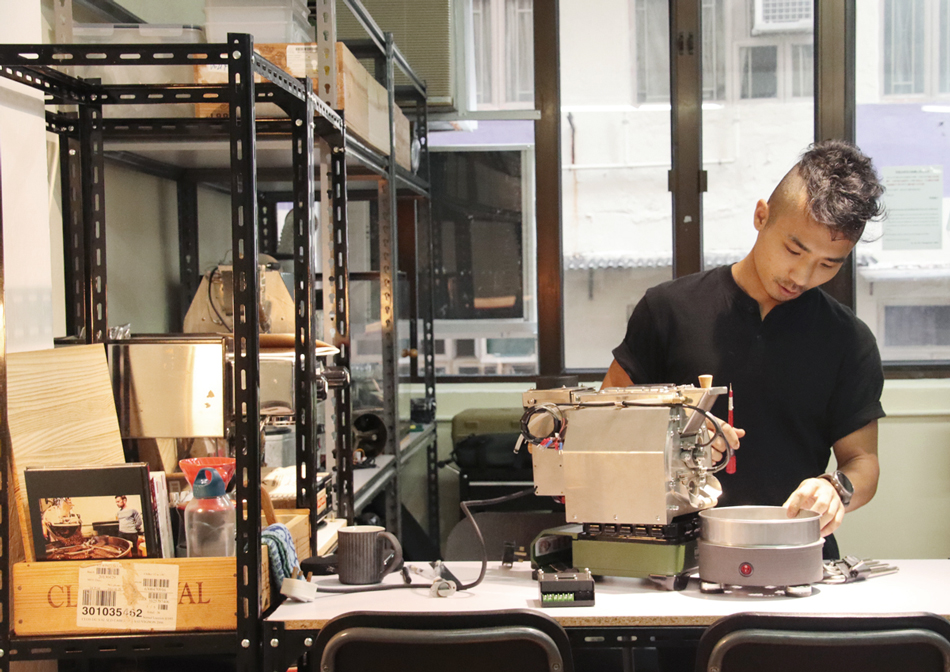

While making a living as barista / product designer / video editor, slasher Naam Yu's true loves lies within his studio Handyman Roasters, where he builds customized coffee roasters, blending creativity with his interests in coffee roasting, product design and metal craft.

“People often ask me which do I prefer, coffee or making roasters? Truth is I enjoy the process of making roasters more than drinking coffee. I am not picky about how my coffee tastes, I’m just happy to drink it.”

After all, the term D.I.Y. (Do It Yourself) seems to be planted in his DNA. "I made all my toys when I was a kid; I was probably influenced by my father, who used to teach woodwork in a school for both students with and without disabilities."

Naam's later got into the Hong Kong Polytechnic University to study Industrial and Product Design. When the faculty interviewer asked for his reason why he chose the subject, Naam replied with humor: "The ability to make problem-solving tools is what made humans wiser than gorillas."

In fact, his quest for coffee roasters was an exercise to stretch his problem-solving skills with better design thinking. "How could we make tastier coffee? Brewing methods only matter in the latter stage, which doesn't affect much, the root of the problem is the way we roast coffee beans."

It all started three years ago, when Naam's design career hit the wall, "then my mother passed away, in the midst of social unrest, everything led me to rethink what I was doing". So he quit his job to focus on his passion: hand brewed coffee. He worked as a part-time roaster, while running various coffee-roasting experiments at home. "I used a clay rice pot for my first trial, after I heard of the trend in Taiwan to roast coffee with ceramic pots." The result? Raw coffee peel flew everywhere, and his apartment cloaked in thick, black fumes. "The coffee was disgusting as hell! Yet I had so much fun in the process."

Naam's very first experiment was to roast coffee with a clay pot, which ended in half cooked, burnt beans.

Blending Old Craft with User-friendliness

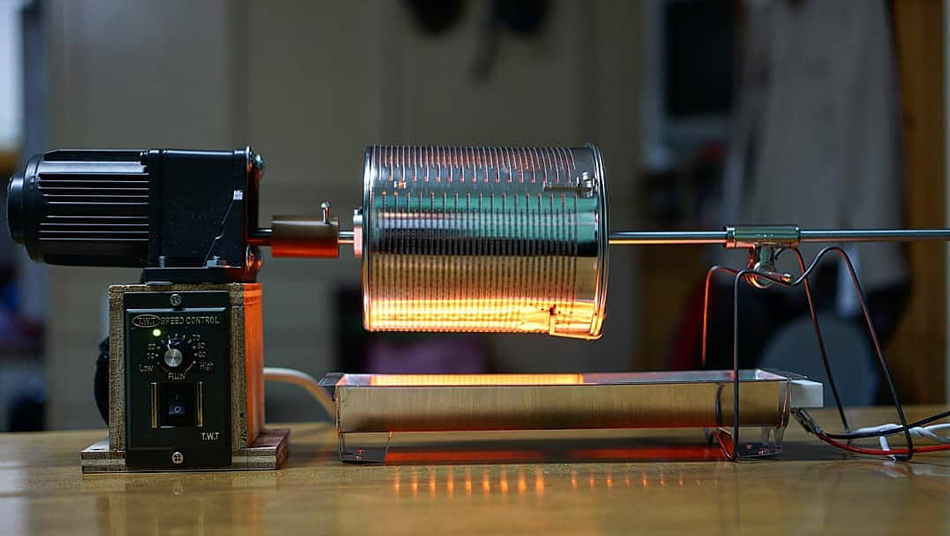

And that clay pot marked the beginning of Naam's roaster-making journey. "I roasted coffee with every cooking appliance I could think of, such as halogen pots and ovens. Then I started building my own roaster with whatever I can get hold at home: grilling rack, hangers, even the little stainless steel tin used to strain Chinese soup."

Full-fledged creativity did not guarantee that every design would be a success, though —eventually Naam sourced out part of his design to manufacturers, based on computerised layout he drew up with his expertise.

Nonetheless, Naam still had a lot of work to do, such as moulding key components of the roaster, made of stainless steel. He invested on a metal-bending machine, thinking it could make life easier, "turns out it was more tiring than working out at gym"! Not to mention the outer shell and countless tiny spare parts that could only be crafted by hand.

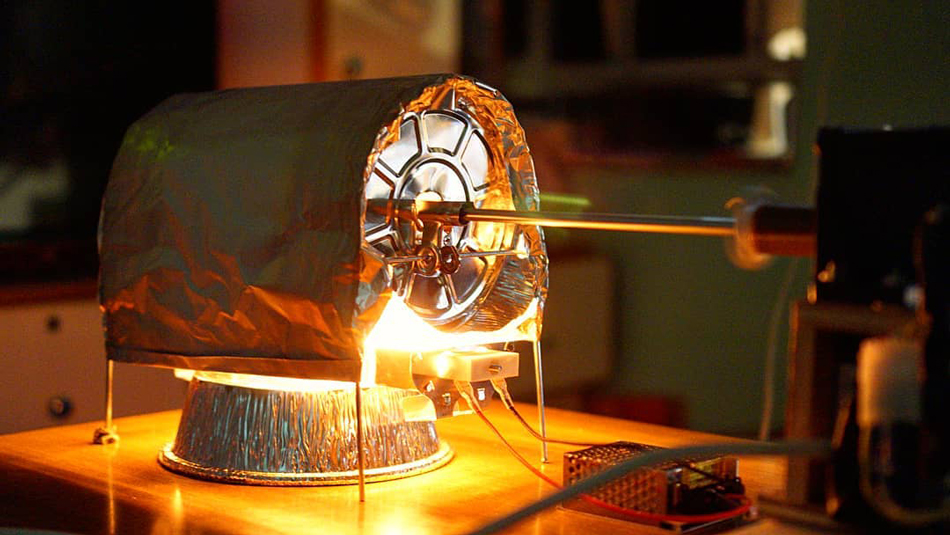

DIY roaster No.1 had a heat wire set underneath a soup strainer; the stand on the right was made out of a coat hanger.

DIY roaster No.2 had a grilling rack covered in foil as the outer shell of the tin, but Naam could not take out the roasted beans on time, as the tin was closed off!

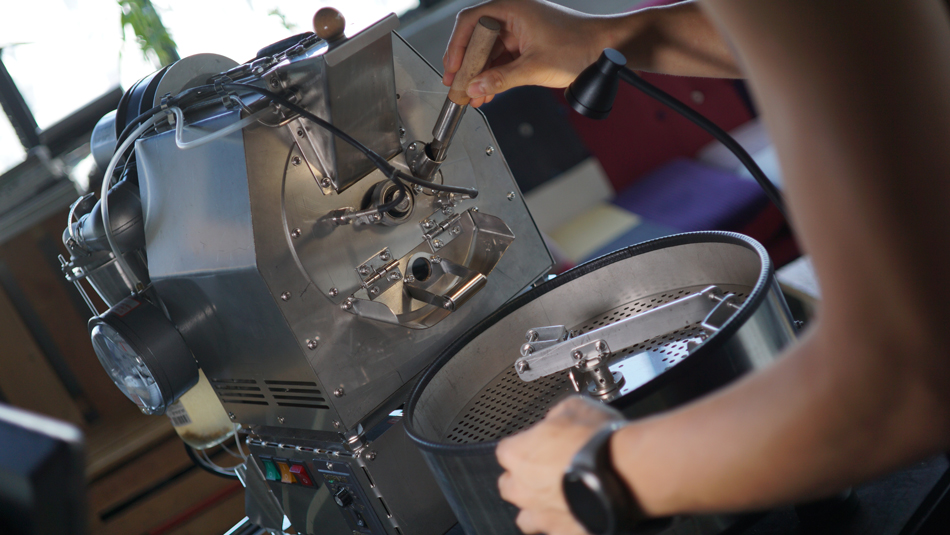

Out of the five roasters Naam built so far, two of them are fully functional, while the others are still "work in progress". Though the roasters are just for his own use, Naam always designs like a pro, with the client's needs in mind. "One of the roasters was meant to be used at home, so I made it smaller and gas stove compatible to suit local households. The larger one was designed for coffee shops, powered by electricity, saving trouble for shop owners to store gas or apply for the necessary license."

A large roaster designed for coffee shops.

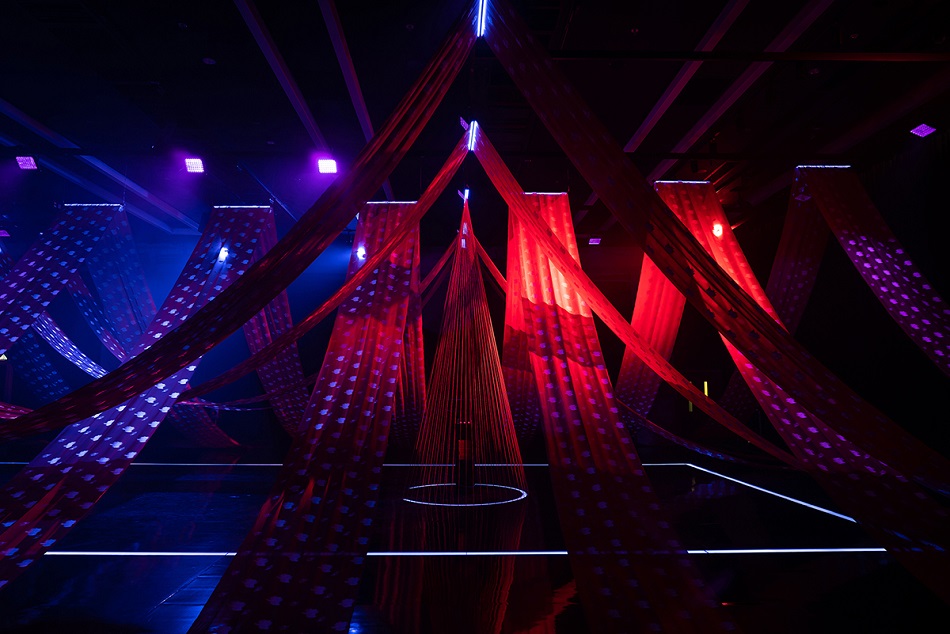

Handyman Roasters' debut at the "Made in Home Kong" craft exhibition, garnering much praise and encouragement for Naam.

Success did not come easy. Welding or hole-drilling was utterly a challenge, as conventional craftsmen found his roaster components "weird" to work on, or didn't know how much to charge him. "I once walked around (the craftsmen district) Tai Kok Tsui all day and couldn't find anyone to drill a hole for me." Naam said. Once again, he decided to take things on himself, "pretty soon I'm gonna learn welding", he said with a smile.

Meanwhile, Naam is learning the craft of galvanized iron from a skilled blacksmith. Traditionally used for mailboxes and tea cannisters, galvanized iron is cheap and heat resistant, making it ideal as the outer shell for roasters. "Besides, it would be meaningful if my work could inherit part of Hong Kong's traditional handcraft." he said.

The blacksmith and another friend also shares Naam's spacious studio, is tucked away in an industrial building. Not only he could cut down on rental costs, and borrow tools from his master whenever he wants. "I find galvanized iron more flexible to work with, I could just cut out pieces by myself."

By building his own roaster, it would be unfair to say that Naam is merely a designer, as he also has the soul of a maker or craftsman; Naam admits he stands "somewhere in between". "What matters most to a craftsman is the satisfaction from his creation, regardless of what other people may think; whereas a designer develops his or her ideas with user-friendliness in mind".

Naam looks forward to the day when coffee lovers could really use his roasters, turning it into a marketable product; on the other hand, his artistic sense tells him that his work is far from done. When does all this effort come to fruition then? "I will keep on working, until I am satisfied with the final product.”

Welding lesson 101: never start without safety precautions!

Beneath the galvanized iron shell, components such as the roasting drum are made of stainless steel, to ensure the beans are safe for consumption.