Interview #09

Connecting Craft and Industry with Bambou

Samy Rio

In our search for sustainable materials, we’ve come full circle. After spending years in the pursuit of biodegradable plastics and eco-friendly ways of obtaining precious metals, the answer could very well grow in our own backyards: bamboo.

It’s one of the fastest-growing woody plants on earth, growing up to 20% a year! Its natural characteristics — strength, pliability, heat-resistance, and hardiness — combined with abundance make it a practical and efficient substitute for plastics and metals.

While the benefits of bamboo are well-known in Asia, it’s a little more surprising that Samy Rio, a French designer, decided to experiment with this wonder material in order to develop a sustainable product manufacturing cycle.

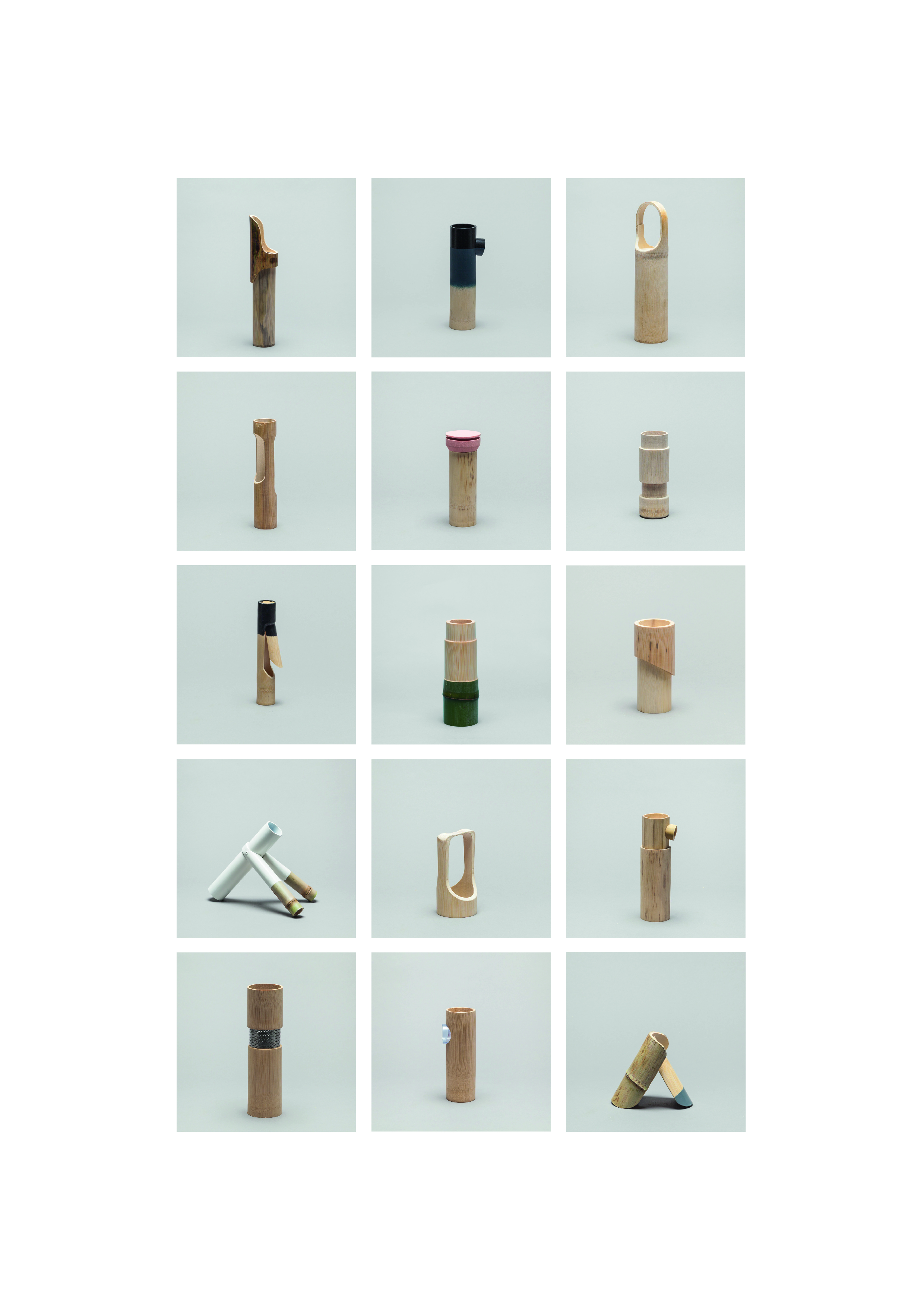

His work, Bambou, won the Grand Prix of the Jury at Design Parade 10. His unique approach, combining traditional craftsmanship with electronic appliance design, resulted in a series of prototype hair-dryers and speakers.

We speak to him to learn about his design process.

RMM: Hello Samy! Can you tell us a bit about yourself and why you decided to study product design?

Samy Rio (SR): I studied cabinet making for 4 years, before studying industrial design. It was a logical choice to make after learning woodcraft. These two disciplines complement each other very well, and my background always gives me 2 ways to start any project, or to think about the production of an object.

RMM: We love your Bambou project! What gave you the idea to use bamboo as an alternative to tubular aluminium?

SR: The plant has always fascinated me — I grew up in one of the rare places in Europe where giant bamboo grows. The idea of this project came from the fact that most industrial products made out of bamboo today are produced from recomposed bamboo board. That’s not a bad thing, but this board needs a lot of glue and energy to be produced, whereas bamboo’s natural tubular form has fantastic properties. It just grows naturally without complicated production or transformational needs — so I chose to propose products made out of bamboo tubes.

RMM: Why did you decide to use bamboo for electronic products?

SR: To showcase bamboo’s properties. This project is more of a research or manifesto project for me. It’s not ready for industrial production because there are so many material tests needed, but the goal was to show that bamboo could be used for such products and industrial applications.

RMM: What were the challenges you faced during the Bambou project?

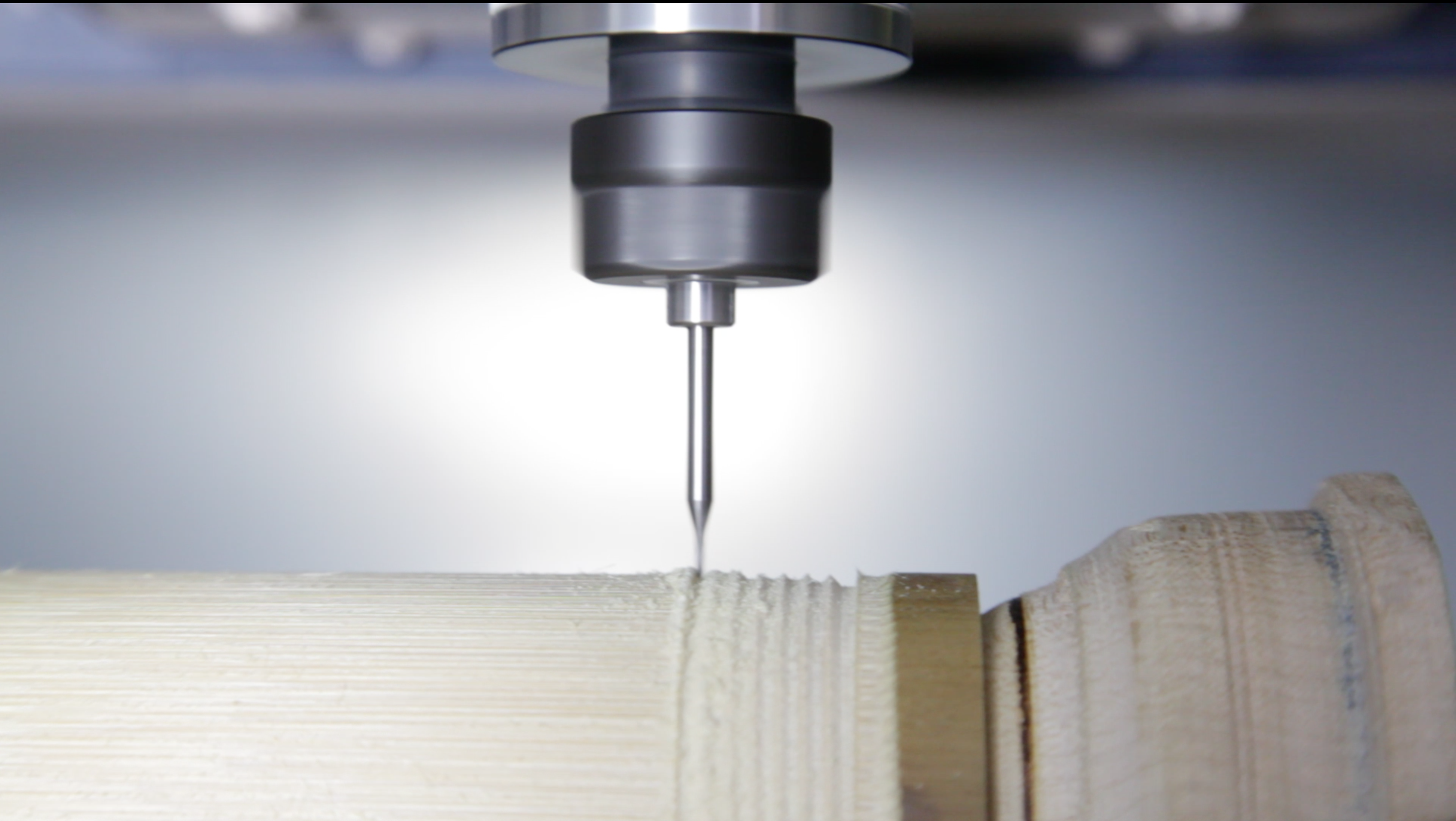

SR: Finding good tools, and an effective method to rectify the bamboo tube in order to create a perfectly round tube.

RMM: What do you love about using bamboo? What's the most surprising thing you’ve discovered?

SR: The most surprising thing I discovered is that bamboo can be used in so many different ways! Lately, we’ve tried working with a glass blower to blow glass inside a tube of bamboo. The glass is 1000°C but the bamboo doesn’t break or burn that much at all! The results were very good. That’s what I love about this material. You can never stop discovering new things to do with it.

RMM: Are there any materials you would like to explore using next?

SR: Yes of course! I’m actually working with glass and ceramic.

RMM: What do you hope to see in the future of design, with regards to the use of natural materials like bamboo?

SR: Natural materials, specifically bamboo, have a lot of really good properties and are sustainable — so we need to use it more when creating objects. But it cannot directly replace the materials we use in industry today. Maybe the point is to use some really good industrial tools, machines, and production systems to produce objects differently with natural materials, and try to avoid mass production, or waste of materials and energy.

Samy Rio's official website: samyrio.fr